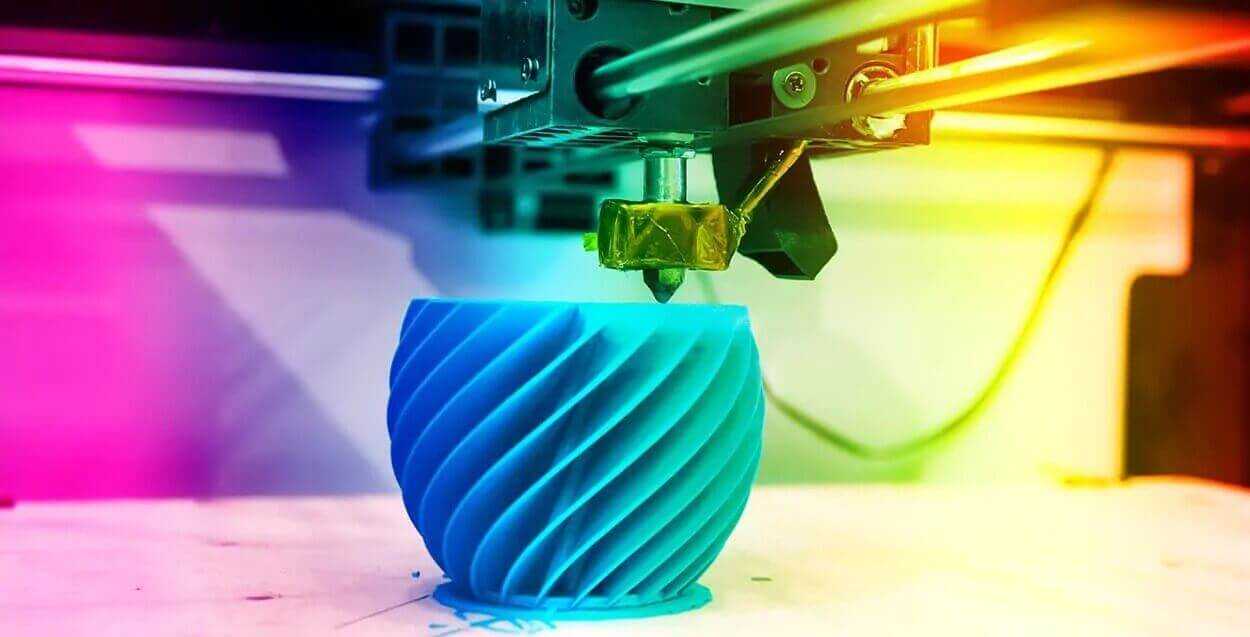

To state that 3D printing technology is changing our world by impacting the manufacturing industry like no other, wouldn’t be an exaggeration.

We are able to find cheaper and stronger products around us. Engineers are reviving their way of thinking by reverse engineering parts and functional prototypes for achieving never before achieved precision.

Experts in this sector believe that no matter whether it’s a nuclear submarine of the US navy or a car for the layman, the software has already become a vital part of how we create things.

There are more lines of code in a car than there are in a cell phone, and the varied aspects of digitization are bringing many disciplines of engineering together.

We are living in an age wherein software, hardware mechanics, and electronics need to work together. It is completely non-relevant to state that this 3D printing revolution can be ignored and its effect can be avoided.

In fact, the opposite of this is very advisable. Hence, if you are an intern, try to get experience with a company that’s working on developing 3D printing or take classes in that company and learn this technology.

There is lots of information available on the Internet about this technology, free of cost.

Making it easier for you to be ready for the future wherein one-day 3D printing technology would be as mainstream as injection molding currently is.

Below mentioned are six areas where the 3D print revolution is happening and you should know.

Also, most businesses are getting benefits from the speedy output of the office laser printers. It suits high-volume office printing.

Contents

1) Aiding Smaller Businesses to Connect With Each Other

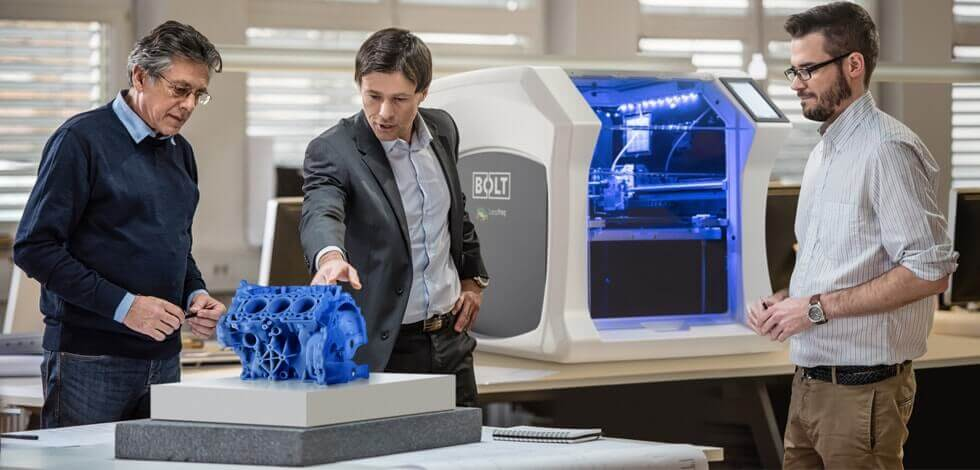

Unlike traditional manufacturing technology which displayed a limited potential in connecting one businessman with the other for work, 3D printing technology enables one businessman in one country to connect with the other businessman in another country.

And this is possible because all the 3D printing projects are based on soft files i.e., 3D design file models.

If today there are a hundred companies connected with each other via the Internet, there are going to be thousands tomorrow.

This will enable smaller companies to contribute to the global chain.

New economies are currently emerging and opportunities are being created as 3D printers become cheaper and easier to work with, nowadays, a 3D printer can cost as low as $300.

If you’re looking for a cheap and affordable 3D printer for your business, check out pick3DPrinter’s list of the best 3D Printers in the $200- $300 range.

2) Production Is Speeded Up at an Unprecedented Pace

Engineers no longer have to care to monitor the complete 3D printing process or undergo the hard work of performing each task themselves. Instead, they can simply click the button to perform an action.

This automation permits them to consume their full time on creative thinking. The basic aim of 3D printing technology is to fulfil your wishes of creating anything that is in your imagination.

And check how closely you can do so. There are 3D printers available in the market with a touchscreen interface, automatic filament loader, filament run-out sensors, automatic bed levelers, etc.

Such features have leveled the speed at which production used to happen by many levels.

3) Engineers Can Afford to Term Tools and Techniques Outdated

3D printing technology allows engineers to be ambitious enough to think of printing circuits using plastic.

They can afford to not think that they are going to manufacture using the same tools such as water-jetting, molds, and dyes. Using 3D printing technology engineers can customize their ideas down to a granular level.

4) Allows You to Fix Problems Remotely

With 3D printers available in the market that grants you the permission to monitor and control them remotely, 3D printing technology lets you get above the biggest limitation of manufacturing technologies to date i.e., being location dependent.

Production plants stand on the same spot for hundreds of years, but with 3D printing, it is possible to set up one at your home, in your basement, anywhere.

It even calls for days wherein you do not have to carry your luggage on your travel, instead, you 3D print whatever you need whenever you need.

5) Helps Engineers to Reimagine Their Already Finished Work

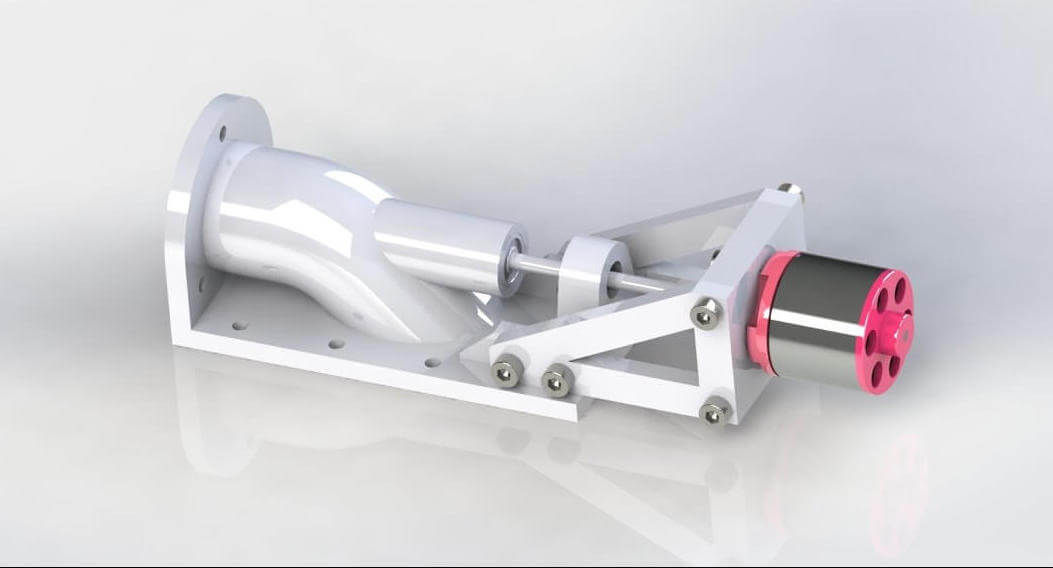

3D printing technology is giving new materials to the world with which parts and functional prototypes can be manufactured.

With additive manufacturing technology we are able to do things that we could have never done before. The parts that are created whereas the form they happen to have are totally unimaginable.

Not only does this give engineers enough power and control, but also it breaks down barriers like never before.

6) Big Companies Are Compelled to Be Harmonious With This Change

3D printing is causing a disruption in manufacturing technology like never before.

It brings in a much more flexible behavior in manufacturing that is unprecedented and very very new, especially to bigger companies that are known to work in a singular way for years.

The whole concept of additive manufacturing as opposed to subtractive is very nuanced. It lets you manufacture parts and functional prototypes without any tooling at all.

The Conclusion

3D printing technology is still in the very initial stage of development. There is a lot that is meant to explore on the software, material, printer as well as post-processing end.

As this technology is growing older with time, it’s also becoming more and more accessible to people and hence developing.

It is changing the way how things were being looked upon in the past. Standardization is no longer a limitation. Mass customization is the most important gift of 3D printing technology.

Even minor edits in standards make a part or functional prototype function in a way that needs reimagination of the complete system of which it is a part.

And when you do so, you realize you have made the complete system function in a much more precise manner than it did before. This is the scale of minuteness that 3D printing technology is able to bring in.

It’s really on the micro level that the improvements are summing up to bring a macro-level change. And everyone in every industry that 3D printing technology is associating with is geared up for this.

The Daily Buzz combines the pursuit of interesting and intriguing facts with the innate human desire to rank and list things. From stereotypical cat pictures to crazy facts about the universe, every thing is designed to help you kill time in the most efficient manner, all while giving you something to either laugh at or think about!